In the power system of new energy vehicles, the drive motor plays a crucial role. This sophisticated energy conversion device is like the "power heart" of a vehicle, responsible not only for efficiently converting electrical energy into driving force, but also for recovering energy during braking, achieving energy recycling. It is precisely this bidirectional energy conversion capability that makes the electric motor one of the core technologies that distinguishes new energy vehicles from traditional fuel vehicles.

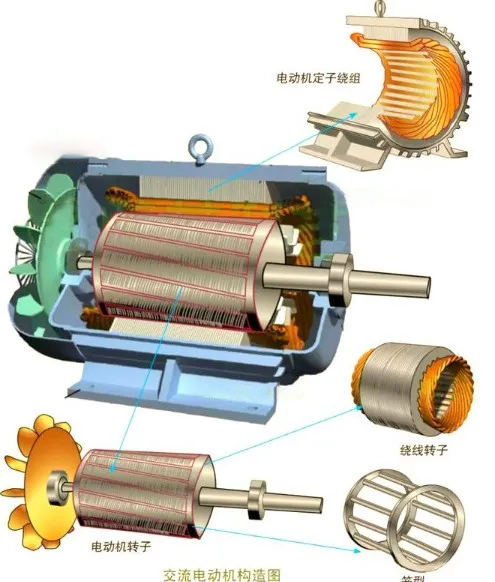

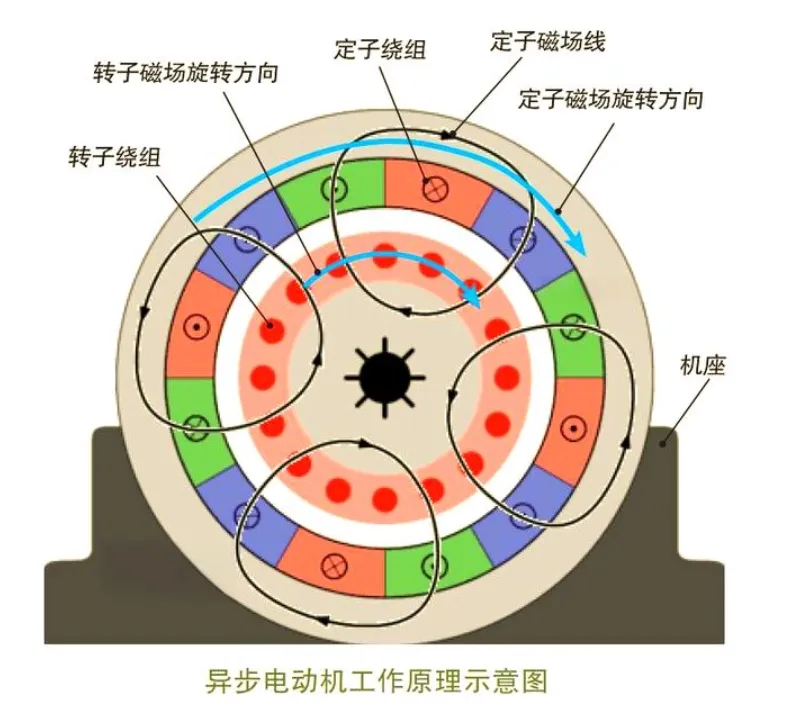

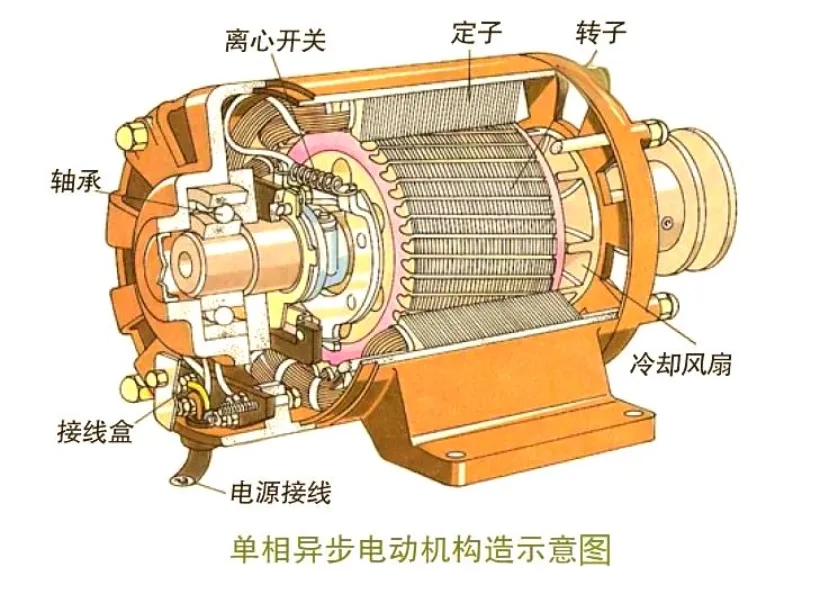

Modern new energy vehicles mainly use two different types of motor technology. Asynchronous motors are favored for their simple structure and low cost. This type of motor operates based on the principle of electromagnetic induction, where the rotating magnetic field generated by the stator induces current in the rotor, thereby generating driving force. Due to the fact that the rotor speed is always slightly lower than the magnetic field speed, this "asynchronous" characteristic gives it good overload resistance, making it particularly suitable for applications that require frequent start stop or high torque output. However, its relatively low energy conversion efficiency also limits its application in high-end car models.

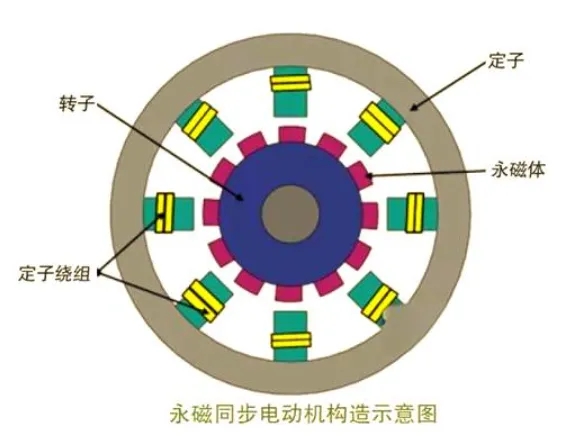

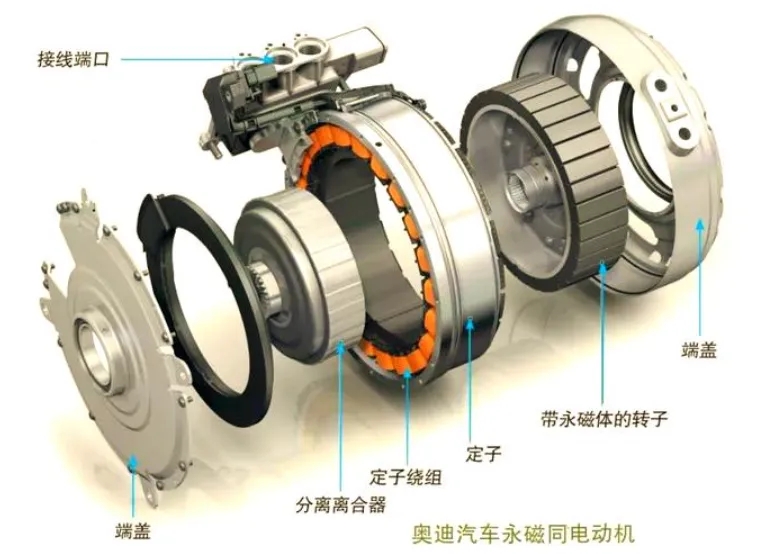

In contrast, permanent magnet synchronous motors have become the mainstream choice in the current market due to their excellent performance. This type of motor uses rare earth permanent magnet materials to manufacture the rotor, which can rotate completely synchronously with the stator magnetic field, and the energy conversion efficiency can reach over 90%. Its excellent power density and fast response characteristics bring stronger power performance and longer range to new energy vehicles. However, the high cost of permanent magnet materials and the potential demagnetization issues that may occur in high-temperature environments have also become challenges that engineers need to continuously overcome.

In order to meet the stringent requirements of new energy vehicles, modern drive motors must possess multiple outstanding performances. In terms of energy efficiency, the energy conversion efficiency of top-level motors has exceeded 90%; In terms of structural design, a significant increase in power density has been achieved through the use of lightweight solutions such as aluminum alloy shells; In terms of environmental adaptability, high-end products can withstand extreme temperature changes from -40 ℃ to 125 ℃ and meet high protection level requirements such as IP6K9K. These technological advancements collectively ensure the reliable operation of motors under various complex working conditions.

In practical applications, the driving motor does not work independently, but closely cooperates with other systems of the vehicle. The intelligent energy management system will monitor the vehicle status in real-time and seamlessly switch between driving mode and energy recovery mode. The advanced liquid cooling system ensures that the motor always operates in the optimal temperature range, which not only guarantees performance but also extends its service life. This system level optimization design has made the power system of modern new energy vehicles increasingly efficient and reliable.

Looking ahead to the future, drive motor technology will continue to innovate. Engineers are exploring new magnetic materials to reduce dependence on rare earths, developing more efficient cooling schemes to increase power density, and applying advanced control algorithms to optimize energy management. These technological advancements will further drive the development of new energy vehicles towards greater efficiency and environmental friendliness, making this' power heart 'beat more vigorously and persistently.