Electric vehicle battery technology is moving towards the core goal of fast charging at an unprecedented speed. The new architecture integrates three major trends, effectively solving the challenges of shortening charging time, improving efficiency, and reducing costs.

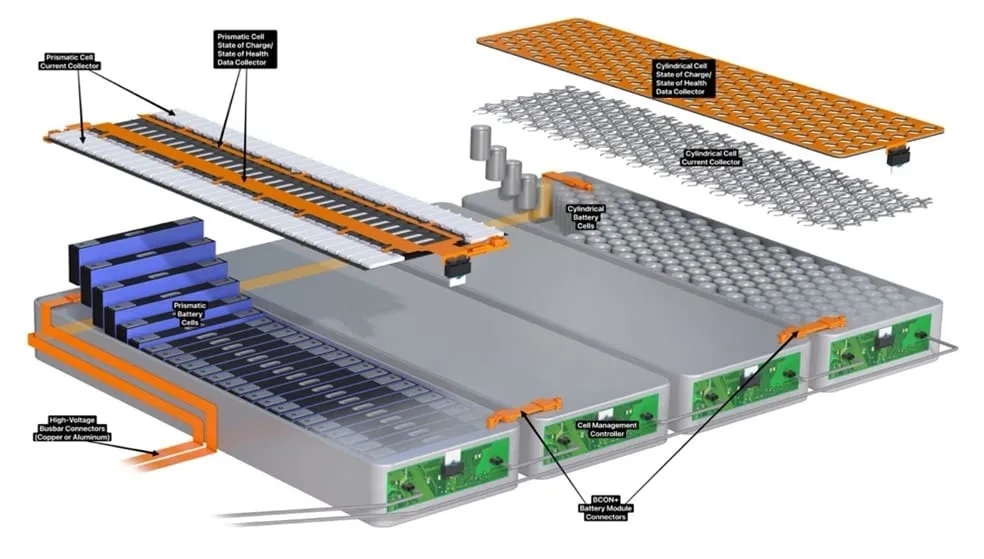

Trend 1: Directly connecting battery cells to battery packs, replacing traditional modules

Eliminating modules and directly integrating battery cells into the battery pack eliminates the occupation of module walls, thereby freeing up more internal space in the battery pack. Boris Ketscher, Product Manager of TE Connectivity's electric mobility, pointed out that "this change has increased the energy density of battery packs, becoming the main means of reducing costs." The new generation of batteries adopts an integrated packaging design, rather than the previous independent module structure.

Traditional modules are small in size and easy to handle manually, making them suitable for the early stages of limited electric vehicle production and assembly that relied on human labor. With the increasing sales of electric vehicles in the past decade, production has fully shifted towards automation. Ketscher said, "When robots are responsible for assembly, weight is no longer a key constraint. This is also why we are now able to achieve a direct connection architecture. However, in the early stages of mass production of the first generation battery packs, this was more difficult

Jan Philipp Trommershaeuser, Product Manager of TE Electric Mobility, added, "The industry is working to eliminate all non value added components in batteries - any part that does not store energy belongs to this category. This idea starts from the level of battery cells: increasing the size of battery cells can save space occupied by terminals, casings, etc. Similarly, removing each module from the battery pack also means eliminating module installation screws, cooling plates, high-power connectors between modules, or sensor cables and bolt connections to the battery management system

Trend 2: Evolution towards higher voltage platforms

The battery voltage is jumping from the mainstream 400V to 800V, which is the key driving force for achieving fast charging. We have seen that Chinese electric vehicle manufacturers have achieved a range of approximately 500 kilometers within five minutes, thanks to high-voltage architectures of 800V and above, "Ketscher said.

Trommershaeuser further looks ahead: 'In the future, there may even be a 1000V system.'. After increasing the voltage, the current can be reduced when transmitting the same power, which not only saves costs but also reduces system losses, thereby improving overall energy efficiency. ”

Ketscher explained, "High voltage architecture allows us to maintain or reduce the cross-sectional area of conductors, which means cables or busbars can use less copper or aluminum material, helping to control costs

However, as the number of cells in the battery pack increases, the number of signal acquisition points connected to the battery management system also increases accordingly. These sensing signals used to monitor temperature and voltage are crucial for charge balance between cells and overall battery health, "Trommershaeuser reminded.

Trend 3: Connectors are developing towards miniaturization and lightweighting

Smaller and lighter battery components help improve energy efficiency and reduce costs. For electric vehicles, weight reduction can directly extend the range, and fast charging is also an important user demand. Raising the voltage to 800V can reduce material usage without increasing the size. Ketscher pointed out, "Otherwise, in order to maintain equal performance, the diameter of all busbars needs to be doubled

As the architecture shifts towards' single cell direct connected battery packs', the scale of sensing cables is also expanding. Ketscher explained, "These flat cables are used to collect temperature, current, and voltage data from each battery cell and transmit it to the battery management system. Currently, they can contain up to 60 conductors." In this context, the spacing between conductors, surface creepage distance, and air gap have become particularly critical. If two conductors are too close and the voltage peak is too high, it may cause arcing. This is a core issue that must be approached with caution in all miniaturization designs, especially at the connection between the battery pack and the battery management system. Successful connector miniaturization must be based on a deep understanding of electrical clearance and creepage distance to ensure reliable performance even in a compact layout

In terms of cost reduction, replacing copper with aluminum has become a clear trend. Ketscher said, "We are assisting our customers in reducing or even completely replacing copper materials, as the cost of aluminum is significantly lower - by about six orders of magnitude. By providing reliable connection solutions, we support our customers in achieving this material conversion

As the "heart" of electric vehicles, batteries are also the most expensive component in the entire vehicle. Continuous technological innovation is continuously reducing its costs, shortening charging time, while improving reliability and energy efficiency, driving electric vehicles towards a broader future.